Features

Meets the design requirements of NFPA Pamphlet 58 for gas/air mixers.

All wiring, controls, electrical components and their installation comply with recognized code standards defined in NFPA Pamphlets 58 and 70.

Explosion proof configuration, suitable for Class I, Division 1, Group D environments.

Factory Mutual (FM) Approved.

Remote mounted PROCESS CONTROLLER (Control Panel) with integral first out annunciator.

Explosion proof junction box with terminal strip for easy field connection to

PROCESS CONTROLLER.

- Air actuated automatic safety shutoff valve.

- High turndown ratio.

- Smooth and rapid response to flow rate changes.

- Manual ratio adjustment or optional automatic ratio control package.

- Skid mounted and complete with all operating and safety controls.

- Rigorous factory testing under strict ISO9001 conditions.

Operation

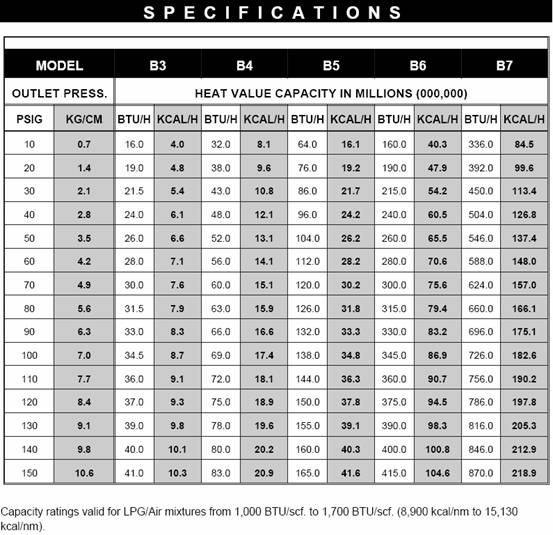

The SDI BLENDAIRE R LPG/Air mixer safely and accurately combines LPG vapor with compressed air to deliver a natural gas compatible mixture at pressures from 10 psig [ 0.7 kg /cm2] to 150 psig [ 10.3 kg /cm2]. The LPG/air mixture created by the BLENDAIRE R will burn with the same character is tics and efficiency as natural gas plus it does not require burner adjustments.

The BLENDAIRER offers high pressure mixing to feed city utilities or supplement natural gas pipe line distribution.

The heart of the BLENDAIRE R is a piston suspended within a three port mixing valve. Com pressed air enters one port. LPG vapor enters another port, and a mixture of LPG/air that is compatible with natural gas discharges from the third port. Horizontal rotation of the piston in creases or de creases the volumetric ratio of LPG vapor to air, hence increasing or decreasing the calorific value of the LPG/Air mixture within a tolerance +/-2%. Vertical travel of the piston in creases or de creases the volumetric flow of LPG/Air. Since the BLENDAIRER is pres sure balanced, it responds quickly to load changes. Both the air line and LPG vapor line have check valves to en sure safe mixing. In addition, sufficient air pres sure must be avail able be fore the gas regulator will open to al low the mixing process to proceed.